MIL-N-58106

3.3.4 Safety. The net design has been safety engineered.

3.3.5 Human Performance/Human Engineering. The net design has undergone

human performance/human engineering,

3.3.6 Standard of Manufacture. The standard of manufacture are specified

by reference to Government and Commercial specifications,

3.4 Major Component Characteristics. The design does not lend itself to

major component characteristics.

3.5 First Article Test. A first article test shall be conducted per

Section 4 on components and assemblies as given in the following.

3.5.1 Net Assy, Part Numbers 6018-5 and 6018-10. One each size net as-

sembly shall be strength tested, In addition, one 10,000 lb capacity net shall

demonstrate original strength repairs that have been accomplished. One each

size net shall be provided and used as a manufacturing standard per repair

criteria given in drawing 6022.

3.5.2 Metalware. Apex fittings and hooks shall be tested in net assemblies

and separately, as required. Parts supplied under contract as end items shall

be tested only as separate items,

3.5.3 Mesh Cord and Border Cord. Cord furnished as bulk material shall be

strength tested. Type XX cord, per Table II shall be evaluated by fabricating

one complete 5,000 lb mesh/lifting leg assembly and testing. Type XXII cord

per Table 11 shall be evaluated by fabricating into one complete 10,000 lb mesh/

lifting leg assembly and testing. Also, the cord shall be fabricated into a

complete mesh/lifting leg assembly to demonstrate ease of repair and original

strength. If both Type XX and Type XXII cord per Table 11 is procured, only the

10,000 lb mesh/lifting leg assembly need be tested to demonstrate ease of repair

aid original strength.

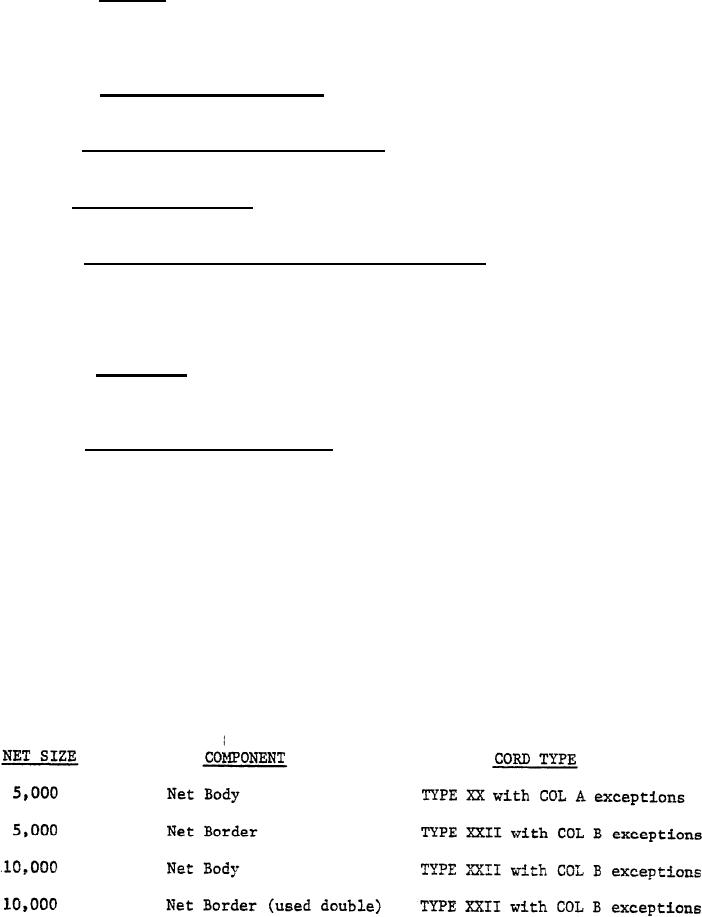

TABLE II

CORD, NYLON CORELESS

The nylon braided cord construction used to construct the net shall be per

MIL-C-7515, cut with the following special criteria.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business