MIL-DTL-27444E

3.13 Dimensional tolerances. Dimensions and tolerances not specified shall be consistent with

best commercial practices. When dimensions and tolerances affect the interchangeability,

operation, or performance of the net, they shall be held or limited accordingly.

3.14 Workmanship. Workmanship shall be of the highest quality to insure proper operation

under conditions to which the nets may be subjected. Unsatisfactory workmanship such as loose,

cocked, or inadequately headed rivets; distorted or loose bushing and pins; loose, broken, or

incomplete stitching and rough malformed, misaligned, or improperly fabricated fittings shall be

deemed defects. Corners shall be rounded, and sharp edges, burrs, or other protrusions that

could damage the webbing shall not be permitted.

4. VERIFICATION

4.1 Classification of tests. The inspection and testing of the nets shall be classified as follows:

First article testing (see 4.3)

a.

b.

Acceptance testing (see 4.4)

4.2 Verification requirements. The verification of requirements shall be in accordance with the

matrix in TABLE IV.

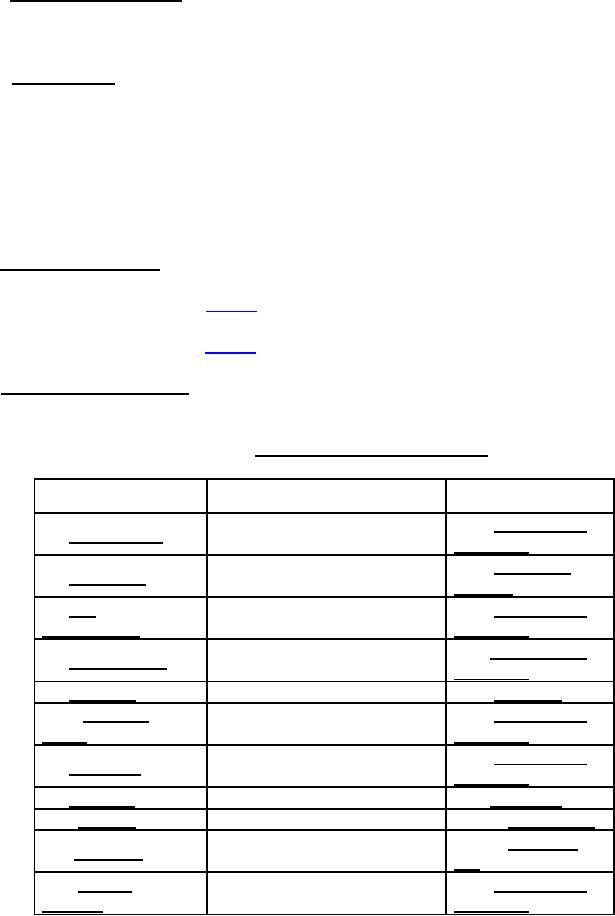

TABLE IV. Requirement verification matrix

REQUIREMENT

VERIFICATION METHOD

VERIFICATION

4.5.1 Examination

3.3 Construction.

Examination

of product.

4.5.3 Reliability

3.4 Reliability.

Analysis

analysis.

3.5 Net

4.5.1 Examination

Examination

configuration.

of product.

4.5.1 Examination

3.6 Net assembly.

Examination

of product.

3.7 Webbing.

Test

4.5.2 Load test.

3.7.1 Webbing

4.5.1 Examination

Examination

colors.

of product.

4.5.1 Examination

3.8 Hardware.

Examination

of product.

3.9 Stitching.

Test

4.5.2 Load test.

3.10 Salt fog.

Test

4.5.4.2 Salt fog test.

4.5.4.1 Vibration

3.11Vibration.

Test

test.

3.12 Special

4.5.1 Examination

Examination

marking.

of product.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business