MIL-DTL-27443F (USAF)

4.3 First article testing.

4.3.1 Test samples. The first article test sample shall consist of 6 pallets representative of the

production pallets except the test samples shall not have skins riveted. The samples shall be identified

with the manufacturer's part number and such other information as required by the procuring activity.

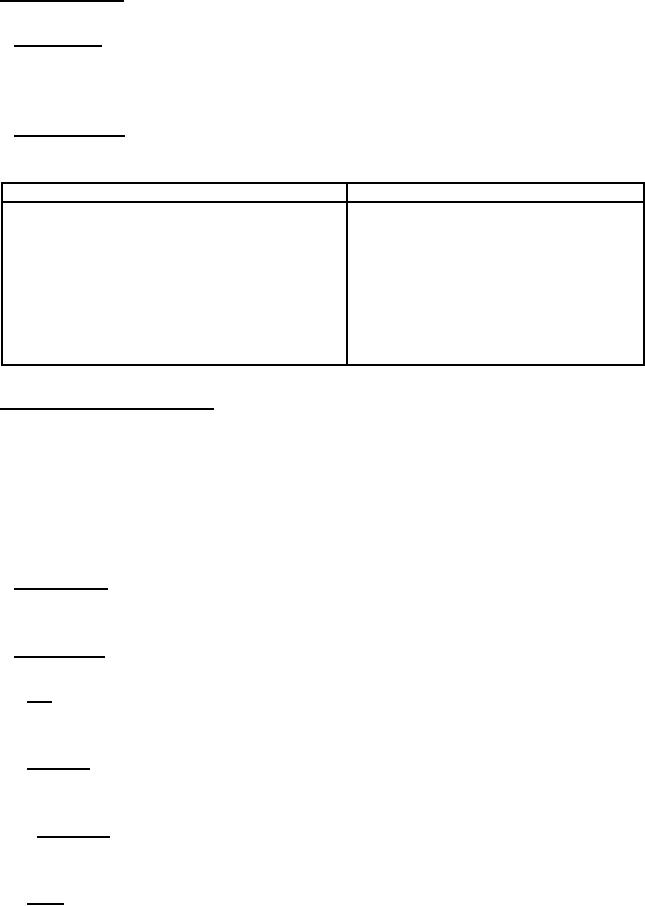

4.3.2 First article tests. The preproduction tests shall consist of all tests described under 4.5 and shall

be conducted on each sample in the following sequence:

Samples No. 1-3

Samples No. 4-6

Examination of product (4.5.1)

Examination of product (4.5.1)

Tap test (4.5.2)

Tap test (4.5.2)

Tie down ring test (4.5.3.1 through 4.5.3.4)

Static load test (4.5.4)

Static load test (4.5.4)

Lifting capabilities tests (4.5.5.1 through 4.5.5.3)

Conveyor test (4.5.6.1)

Ultimate load test (4.5.7)

Environmental tests (4.5.8)

Destruction analysis (4.5.8)

Destruction analysis (4.5.9)

4.4 Quality conformance inspection. The quality conformance inspection shall consist of the following:

a. Individual test (see 4.4.1)

b. Sampling test (see 4.4.2)

c. Adhesive testing (see 4.4.3)

4.4.1 Individual test. Each pallet shall be subjected to the test specified (see 4.5.1, 4.5.1.1, and

4.5.11).

4.4.2 Sampling test.

4.4.2.1 Lot. A lot shall consist of pallets manufactured under the same conditions and submitted for

inspection at the same time.

4.4.2.2 Sampling. Sampling for examination and tests shall be in accordance with ANSI/ASQC Z1.4,

general inspection level II, single sampling plan for normal inspection.

4.4.2.3 Examination. Samples selected in accordance with 4.4.2.2 shall be examined as specified (see

4.4.2.5).

4.4.2.4 Tests. Samples selected in accordance with 4.4.2.2 shall be tested as specified in 4.5.5.1.

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business