MIL-DTL-25959H

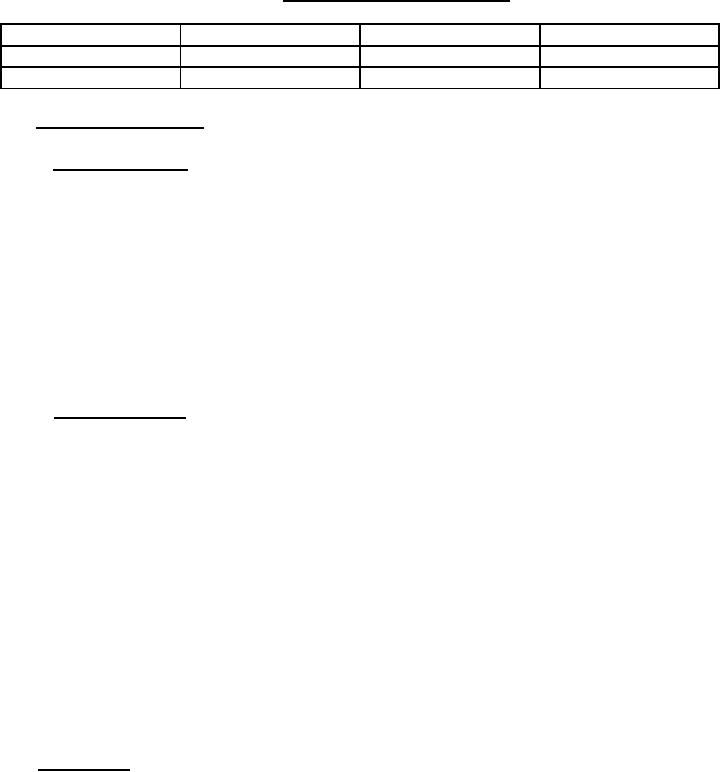

TABLE I. Tie down tensioner dimensions.

Tie down

Length

Width

Height

CGU-8/A

16 inches

4 inches

3.5 inches

CGU-7/A

18 inches

5 inches

4 inches

3.6 Tensioning capabilities.

3.6.1 Tensioning ability. After preliminary adjustment of the tie down tensioner to remove

excess slack in the chain, the tensioning assembly shall be operational and shall be capable of

applying tension to the chain of not less than 300 lbs with a manually applied torque of not more

than 60 inch-pounds acting on the tensioning adjustment control. Additionally, no component of

the tie down tensioner shall fail when torques up to 85 inch-pounds are applied to the tensioning

adjustment control, in the tensioning direction while the tie down tensioner is fully retracted, and

in the loosening direction, when in the fully extended position when tested as specified in

4.6.6.1. Failure is defined as catastrophic as well as permanent deformation of components. The

tensioning adjustment control shall have a minimum height of 1 inch. It shall be of circular

design with raised area to aid grip during tensioning and shall have at least eight locking

positions per 360o rotation.

3.6.2 Tension releasing. The tie down tensioner shall be so designed such that the chain

assembly (component attached to the cargo) can be manually released and automatically

separated from the tie down tensioner with one hand in a single operation with an applied force

not exceeding 50 lbs while restraining loads that apply 5,000 lbs of tension on the chain. It shall

also be possible by the application of additional force not to exceed 100 lbs (for both Types III

and IV devices) to safely release the chain assembly from the tie down tensioner while

restraining loads that apply 10,000 lbs of tension for the CGU-8/A device or 25,000 lbs for the

CGU-7/A device when tested as specified in 4.6.6.2. Any release mechanism which results in

any component of the tensioning assembly becoming detached or damaged or does not permit

the tie down tensioner to be immediately reapplied shall not be acceptable. The tie down

tensioner shall be capable of releasing sufficient tension for the chain to be released in a safe

manner solely by using the tension release mechanism. The mechanism shall be designed in

such a manner that inadvertent release of the mechanism by personnel moving about the aircraft

does not occur. Any design which requires operating personnel to exercise extreme caution in

releasing the tie down tensioner under the proof loads cited in this specification shall not be

acceptable.

3.7 Components. Installed cargo tie down tensioner assemblies consist of a chain assembly,

conforming to MIL-DTL-6458, attached to a tie down tensioner as follows:

a. Type I chain assembly with CGU-8/A

b. Type II chain assembly with CGU-7/A

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business