MIL-DTL-9401C

3.3.6.3 Zigzag stitching. Zigzag stitching that is parallel to straight stitching shall normally not

overlap the straight stitching. When only one row of zigzag stitching is specified, it shall be

centered. Unless otherwise specified, the tolerance for the length of the row of zigzag stitching

shall be + ½ or 0 inch. The distance between the nearest edge of the zigzag stitching and the

edge of the material or seam and the distance between the adjacent edges of the rows of zigzag

stitching on the drag surface shall be not less than 1/8 inch.

3.3.7 Automatic sewing machines. Automatic sewing machines may be used for sewing stitch

patterns provided that the size of the pattern, the thread size, and the number of stitches per inch

specified in the detail specification are maintained. A minimum of three tie- in, overlapping or

back stitches shall be used to secure the ends.

3.3.8 Seams. Seams shall conform to ASTM D 6193. Seams shall be flat and smooth to

preclude pleating, ragged edges, cloth edges not properly caught, and puffiness of fabric

between. Every effort shall be made to produce a fully folded flat seam. Excessive puffiness in

the seams shall not be acceptable, because it tends to reduce the fullness in the rows of the

stitching gores causing stresses in the seams during canopy inflation which may cause damage or

failure. Finished fell and hem seams showing raw edges shall be repaired. Seam margins that

are less than 1/16 inch, but not beyond the edge of seam or material, will be acceptable for a

distance of 2 inches spaced not less than 36 inches apart.

3.3.9 Splices. Splices of webbing tapes, and ribbons used in assembling the canopy, except the

vent reinforcement web, shall be held to a minimum and shall not exceed the number specified in

table II. Only one piece of webbing shall be used in the vent hem. When two or more layers of

the same material are used in a seam, one layer shall be continuous across the splice of the other

layer. Unless otherwise specified, the ends of the splice shall be made by overlapping the ends

for a dis tance of not less than 4 inches.

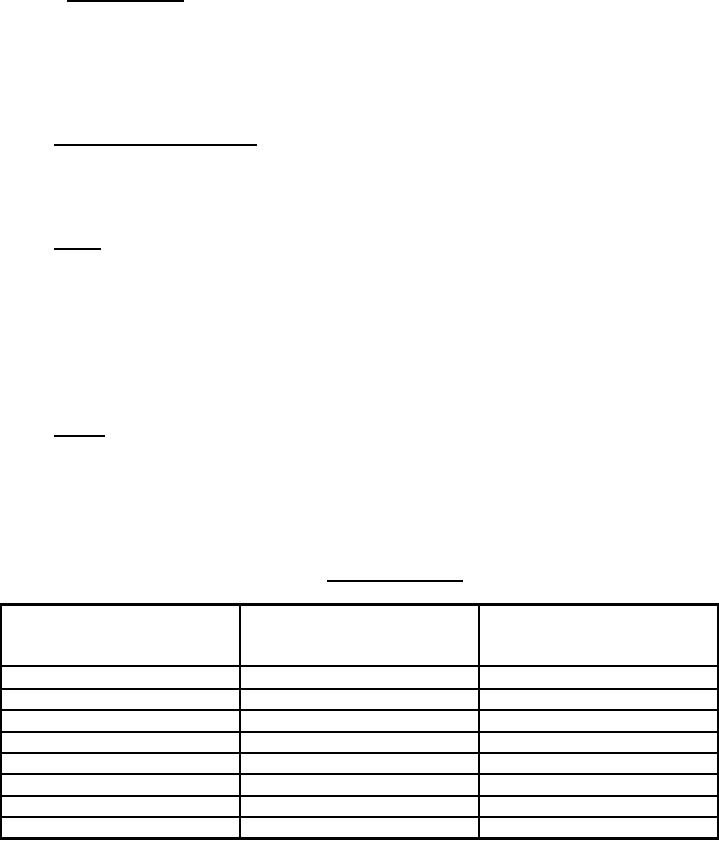

Table II. Number of Splices

Length of seam

Number of splices

Number of repairs

(inches)

permitted

permitted

0 to 2

0

0

2 to 12

0

1

12 to 72

0

2

72 to 240

1

3

240 to 360

2

4

360 to 480

3

5

480 to 600

4

6

Over 600

1 per 120 inches

1 per 100 inches

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business